Grenzebach BSH GmbH

Booth number: SS2D88

www.grenzebach.com

About us

Grenzebach is a reliable journey partner for its customers in the building materials industry.

As a full-line partner, Grenzebach offers a wide range of production solutions for the gypsum industry. The company provides custom-tailored equipment to produce wallboards, gypsum blocks, and various types of gypsum plaster. With many years of experience in the industry, Grenzebach brings in-depth expertise to the processing of natural, synthetic, and recycled gypsum.

Furthermore, Grenzebach offers veneer manufacturers the entire range of plants and machines for veneer drying: From individual dryers with manual feeders, to complete veneer drying lines with scanners and stackers. Grenzebach is a specialist for high-quality veneer production, having realized more than 400 plants worldwide. In-depth expertise regarding different veneer types provides customers with an individual fine-tuning of the technology to their requirements.

A full range of equipment and systems for producing, processing, and finishing of insulation materials, from individual dryers with feeders and manual unloading stations to complete production lines with scanners and stackers is also offered by Grenzebach. The company specializes in high-grade insulation materials production and has supplied plants for cellulose insulation material, wood fiber insulation boards and mineral wool to customers worldwide.

From raw material analysis and testing in its own technical center (Bad Hersfeld, Germany) to plant engineering and commissioning, Grenzebach supports its international customers with profound know-how and expertise throughout the equipment’s entire lifecycle.

Address

Rudolf-Grenzebach-Str. 1

36251 Bad Hersfeld

Germany

E-mail: info.gbsh@grenzebach.com

Phone: +49 6621 813000

Internet: www.grenzebach.com

Plot No. PAP-K-8/1, Chakan Industrial Area, Phase II, Village Khalumbre, MIDC, Taluka-Khed

410501 Pune

India

E-mail: info.gpun@grenzebach.com

Phone: +91 976 6950700

Internet: www.grenzebach.com

No. 100 Chenggong Rd., Huimin Str.

314100 Zhejiang, Jiashan County

China

E-mail: info.gj@grenzebach.com

Phone: +86 573 8499-8000

Internet: www.grenzebach.com

10 Herring Rd.

30265 Newnan, Georgia

United States

E-mail: info.gn@grenzebach.com

Phone: +1 770 2534980

Internet: www.grenzebach.com

Contact person:

Dennis Schattauer

Sales Director Building Materials

E-mail: info.gbsh@grenzebach.com

Phone: +49 6621 813000

Production Technology for Flexible Wood Fiber Insulation Batts

Grenzebach provides complete production technology for manufacturing flexible wood fiber insulation products—from dried wood fiber to packaged insulation batts. Whether individual components or fully integrated production lines, our solutions cover the entire production process: mixing, forming, curing, processing, refining, and packaging.

As a reliable partner, Grenzebach supports you in developing innovative insulation production projects—from plant design to commissioning, always efficient, trustworthy, and future-focused.

Sustainable Stone Wool Production Through Innovation

Grenzebach has developed a sustainable stone wool production line in response to rising energy costs and growing demand for insulation materials. This line, which uses basalt and dolomite as its primary raw materials, is a testament to our commitment to environmental sustainability. The process begins with melting these stones in a furnace, followed by fiberization using a spinning machine. The fibers are then formed into a continuous fibrous web, which is processed through a curing oven. Finally, the cured product is cut and handled to produce the final boards at the cold end.

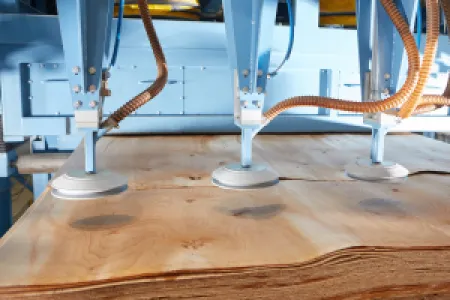

Advanced Veneer Drying and Optical Surface Inspection Solutions

Grenzebach offers veneer manufacturers a complete range of drying solutions, from individual dryers with manual feeders to fully automated drying lines with scanners and stackers. With more than 400 plants installed worldwide, Grenzebach is a trusted partner for high-quality veneer production. The AI-supported ROSI (Real-Time Optical Surface Inspection) system provides precise, real-time surface inspection, reducing scrap and optimizing material flow. With over 60 years of drying expertise, Grenzebach also modernizes existing veneer dryers, including Babcock models, to meet today’s performance standards.

Cutting-Edge Production and Energy Efficiency in Gypsum Wallboards

Gypsum plasterboard plays a key role in modern interior design, offering versatility and high performance when raw material properties and end-product characteristics are precisely aligned. Grenzebach draws on decades of expertise to deliver tailored production lines that provides premium quality gypsum. A standout innovation is the Ultra High-Efficiency Dryer (UHE Dryer). Compared to the best available dryers, it saves up to 33% in energy through a sophisticated combination of high- and low-temperature sections, including a transition zone. The low-temperature section utilizes 100% waste heat, reaching values of up to 400 kcal/kg. In addition, the dryer recovers between 45% and 50% of water, and is compatible with renewable energy sources and low-calorific heat — an industry first. This efficiency enables significant cost savings, and supports sustainable production processes.

From Raw Material to Stucco or High-Fired Plaster

The capabilities of gypsum as a building material depends to a great extent on the chemical composition of the raw material. To provide targeted, high-quality processing into gypsum plaster, plasterboard or gypsum blocks, you need technology solutions that process natural or synthetic gypsum into stucco or high-fired plaster. With its in-depth know-how, Grenzebach fine-tunes calcination specifically to the nature of the raw material, the properties of the end product, and individual operating parameters such as capacity and available energy sources.