OMAG Maschinenbau GmbH

Booth number: SS3C79

omag.de

About us

Since 1948, OMAG has stood for more than just outstanding machines – we stand for values that characterise our actions:

Trust, quality and innovation. With a deep understanding of our customers’ needs, we develop machine solutions that are not only powerful, but also sustainable and future-proof.

Integrity is at the core of our work – we deliver not just products, but promises you can rely on. Our machines are the result of a passion for excellence and a relentless pursuit of perfection to meet the demands of a changing world.

Companies around the world rely on OMAG because we take responsibility – not only for the quality of our products, but also for the sustainability and success of our customers.

Our excellent customer service is not just a service, but a sign of our commitment to a partnership based on honesty, respect and long-term trust.

OMAG – machines that can do more.

Partnerships that offer more.

Address

Westfalenstr. 2

26723 Emden

Germany

E-mail: info@omag.de

Phone: +49 4921 805-805

Internet: www.omag.de

Contact person:

Tim Carvalho

Dep. Sales Director

E-mail: tcarvalho@omag.de

Phone: +49 175 6541693

Katarzyna Zwierzynska

Sales Director

E-mail: kzwierzynska@omag.de

Phone: +49 171 2643593

Products & Services

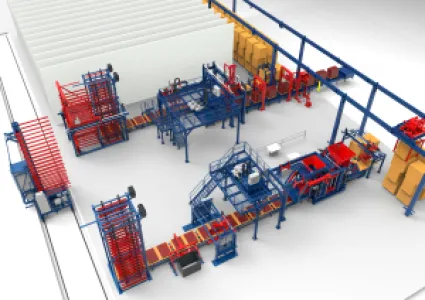

OMAG Maschinenbau GmbH is a long-established manufacturer of machinery and equipment for the concrete block industry, based in Emden, Germany. For more than 75 years, the company has been developing and producing high-quality, technologically advanced solutions for customers around the world. OMAG specializes in concrete block machines that stand out for their precision, reliability, and modular design. The company offers complete production lines including conveying systems, control technology, and automation solutions. In addition to manufacturing, OMAG provides project planning, commissioning, and global service. The combination of extensive experience, innovation, and customer-focused development makes OMAG a leading supplier in the industry.

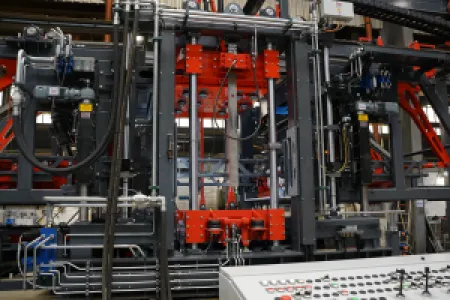

OMAG Tronic Block Machine

The OMAG Tronic concrete block making machine is available in multiple configurations to suit various production requirements. It supports board sizes ranging from 1,300 x 700 mm up to 1,550 x 1,400 mm, depending on the model. The machine is capable of producing concrete products with heights from 15 mm to 600 mm, offering exceptional flexibility for manufacturers. Designed with servo-electric and hydraulic drives, the OMAG Tronic ensures fast, precise, and powerful motion sequences. Its robust construction and modular design allow for customized setups, including automatic mold change systems and intelligent control technology. The machine is engineered for continuous operation and high output, making it ideal for industrial-scale concrete block production.

OMAG Finger Car

OMAG finger car systems offer safe and efficient transport of concrete blocks.

Adaptable to individual project requirements.

Equipment options:

Rotating device

Support arm adjustment

Maximum product diversity through flexible equipment.

Head guidance prevents unwanted movements of the superstructure for precise entry into chamber systems or lifting and lowering scaffolding.

Integrated laser board detection prevents production documents from remaining on the forks.

Data transmission via WLAN.

Distance measurement via laser.

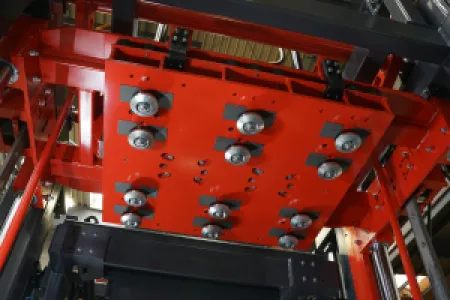

OMAG Servo Cuber

Efficient, dynamic and maintenance-free – for maximum precision in your concrete block plant

Fully powered by servo motors

Harmonious movement sequence thanks to servo technology

Travel drive via flat belts offers short cycle times even on long journeys

Lifting frame with high rigidity even for heavy products

Up to 270 degree turning radius

Maintenance free

No oil stains on products

Can be integrated into existing systems or self-sufficient

Board Stack Buffer Car

OMAG cross transport solutions for storing production boards ensure continuous production of your system.

Depending on the buffer size, the concepts may vary:

Board package cart

Vehicle groups

Roller conveyors

Crane systems

Optionally, the buffer can be expanded using shelving systems.