RATEC GmbH

Booth number: SS3B69

www.ratec.org

About us

RATEC is a leading provider of magnetic formwork technology and mould solutions for precast concrete production. With the development and production of smart magnetic formwork components we have set global standards in the past 30 years.

RATEC is a family-run business and part of the Reymann group of companies. Together with Reymann Technik, the engineering office for planning and realisation of precast concrete production plants, we provide end-to-end-solutions as a partner in your precast journey.

Our 3D mould portfolio provides smart forming solutions for modular construction projects, transformer compact stations, bathroom pods, elevator shafts and other room units. They are designed for a long-term efficiency and flexibly adaptable for the production of precast concrete room modules.

Upcrete® technology with battery moulds and a concrete pump station completes the product range and is especially used in projects with very high surface quality requirements.

Benefit from our experience, flexibility and creativity : MEET THE BETTER IDEAS!

Address

Karlsruher Str. 32

68766 Hockenheim

Germany

E-mail: info@ratec.org

Phone: +49 6205 940729

Internet: www.ratec.org

P. O. Box 17872

Jebel Ali

United Arab Emirates

E-mail: webau@eim.ae

Phone: +971 4 8860662

Internet: www.webau.ae

Contact person:

Koeksal Kervan

Regional Sales Director

E-mail: kkervan@ratec.org

Phone: +49 6205 940731

Products & Services

Shuttering magnets, Shuttering systems, Formwork handling equipment, Adapters for the fixation of shuttering material, Insert magnets & electrical box magnets, chamfer strips/magnetic reveal strips, Special formwork development & construction Battery Systems, 3D mould solutions for room modules, bathroom units, transformer stations, datacenters etc., Upcrete® pump station UPP Universal concrete inlet, Upcrete® modular housing production technology, Production consultancy.

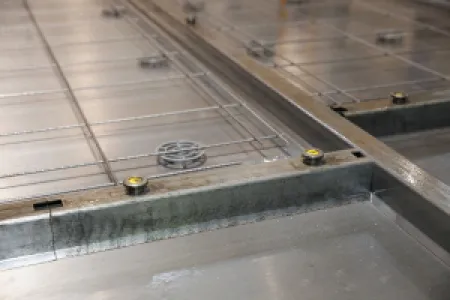

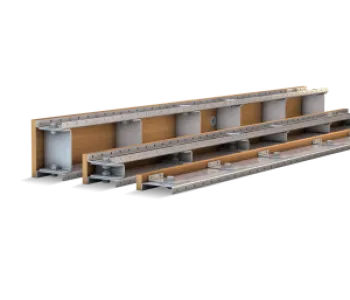

Magnetic formwork technology

Profit from the benefits of leading formwork technology. RATEC develops and produces shuttering systems, shuttering magnets, assembly magnets and special formwork solutions according to the requirements of precast concrete plants and the individual customer’s needs, with the main objective to lower installation costs and to improve the quality of precast concrete elements.

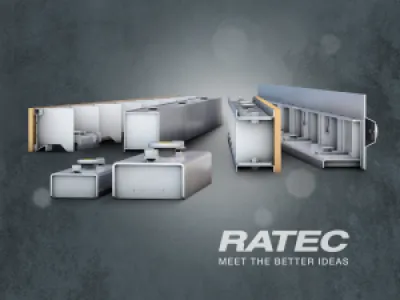

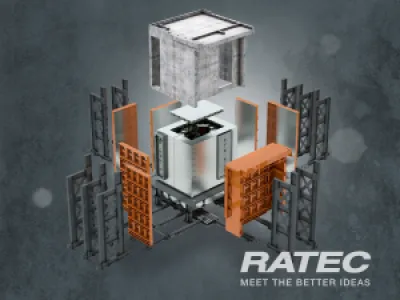

3D mould solutions

We have significantly expanded our formwork portfolio for the production of volumetric precast concrete elements. With the modular mould kit for complex requirements production of 3D elements can be economically feasible even with smaller series. The combination of different basic components, which can be flexibly combined, allows the mould to be adapted to other element sizes. Furthermore, our 3D mould portfolio includes solutions for transformer stations, lift shafts or sanitary cells.

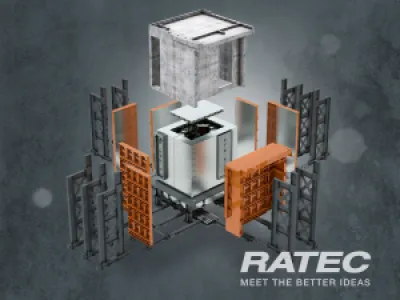

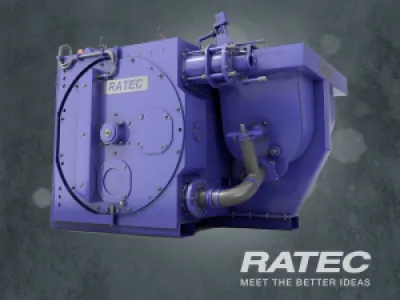

Upcrete® Technology

With upcrete® RATEC introduced a new dimension of precast concrete element quality. Almost every imaginable precast concrete element geometry can be manufactured with upcrete® in one work operation. For this, self-compacting concrete is pumped from below into a (partially) closed form. The flexibility of the system offers unique possibilities for design, element geometry and production process – with maximum quality and formwork-smooth surfaces on all sides at the same time.

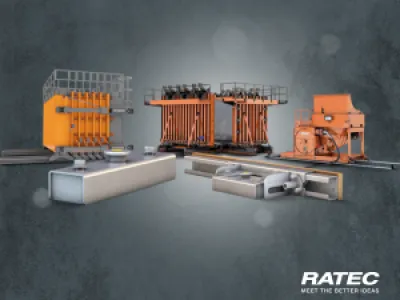

Battery Systems

The pocket battery moulds from RATEC incorporate all the creativity and engineering know-how of more than 40 years of experience in the development and rationalisation of precast concrete plants.

Together with the proven upcrete® technology, our pocket battery moulds prove their high quality and cost-effectiveness day after day across three continents. However, they can also be filled conventionally from the top. The end product is characterised by smooth surface concrete on all sides as well as by the smallest geometric tolerances.

The moulds also impress with their ease-of-use and sturdiness, with a stable pressure-resistant design, so that each pocket can be filled seperately.

Tensioning of the pockets is possible hydraulically or mechanically. The battery system is available as single or twin set-up and is expandable to 2 x 10 pockets.

Vibration for compaction, movable working platform and additional magnetic formwork components are available on request.

-thumb.webp)

-thumb.webp)

-thumb.webp)

-thumb.webp)

-thumb.webp)